Tariffs Lit the Fuse—Robotics Is Your Rocket

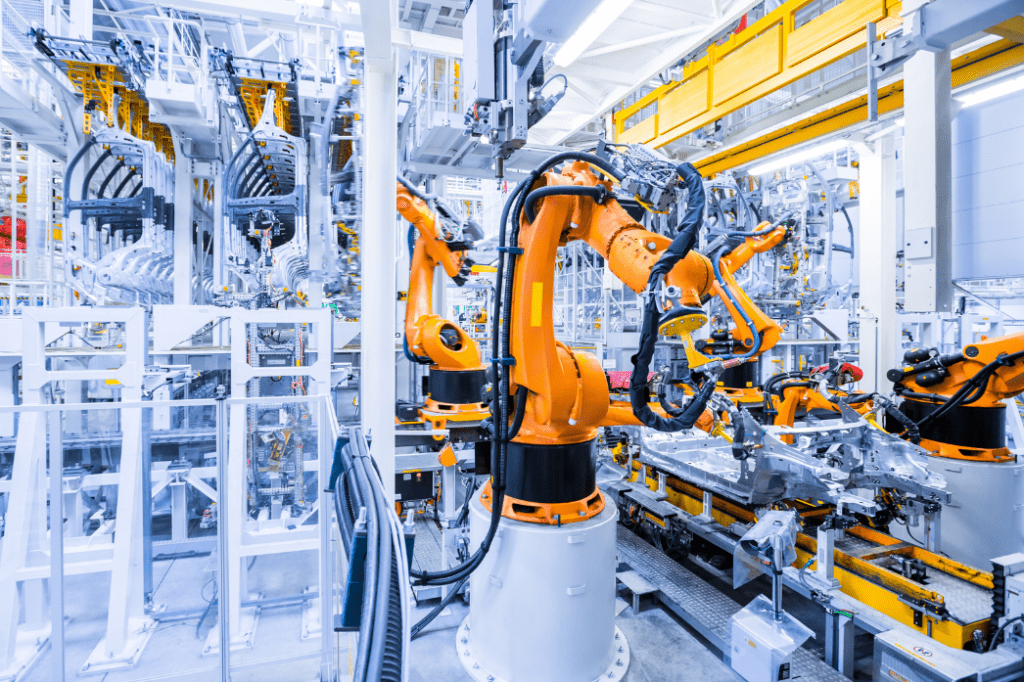

Manufacturers, the clock’s ticking. As of April 9, 2025, the U.S.’s 104% tariff on Chinese goods and Canada’s 25% retaliation are strangling imports—$439 billion from China, $50 billion in auto exports, gone. Reshoring’s the play, and robotics is the muscle: 2.5 robots per 100 workers scaling fast to outpace $15/hour labor costs. But without an ERP that syncs automation, you’re dead in the water—wasted output, bloated inventory, lost margins.

Generic ERP—SAP, Oracle—chokes on robotics. Too slow, too stiff, $150K for a half-baked tweak. You need custom ERP that welds automation to your business—real-time, lean, brutal. Here’s how to integrate it in 2025 with five steps that turn tariffs into triumph. No hype, just horsepower. Let’s roll.

1. Assess Your Line for Robotics Readiness—Don’t Guess

A $50K robot’s useless if your floor’s a mess. Custom ERP maps the battlefield.

- Action: Build an ERP audit tool—inputs: line speed, labor cost, output gaps. Example: 500 parts/day manual at $20/part vs. 700 robotic at $15. Takes 72 hours to spec.

- How: Pull production data (CSV export), run a cost-benefit calc—labor vs. robot ROI. Checklist: power supply, space, maintenance crew. Done.

- Win: Spot $2M in automation upside on a $10M line—your green light.

Pro Tip: We’ve audited 20+ lines this year—get a free readiness checklist below.

2. Connect Robotic Output to ERP—Real-Time or Bust

Robots pump 24/7—your ERP better keep up. Sync it, or bleed cash.

- Action: API your robots (FANUC, Universal) to ERP—track units, downtime, costs. Example: 1,000 PCBs/day at $10 each, $200 downtime flagged. ERP updates inventory live.

- How: Grab robot SDKs (free online), code a data bridge—one week, $2K if outsourced. Test it: 99% uptime or bust.

- Win: $10M in output tracked, $500K in downtime slashed—pure profit.

CTA: Need the API hookup? Our ERP demo’s got it—book it now.

See How My Company Can Massively Automate Your Company Departments

Custom CRM Development – For Organizations to manage its Customer Interactions in addition to Sales, Marketing, Billing, Products, Services, Contacts, Customer Support, among other things.

Custom ERP Development – For Manufacturers to handle BOM, Quotation, Order, RFQ, PO, SOA, Manufacturing, Trading, Inventory, Quality Control, Logistics, Shipments, and so on.

3. Forecast Demand with ERP-CRM Link—Don’t Overbuild

Tariffs shift markets—30% toy hikes, $50B auto losses. Sync ERP robotics to CRM demand, or you’re stuck with scrap.

- Action: Pull CRM sales trends into ERP—example: 20% auto parts spike post-Canada tariffs. Adjust robotic runs: 800 units/day to 1,000. Auto-forecasts adjust weekly.

- How: API CRM (your sales data) to ERP (production)—three-day job. Sample query: “If Canada drops 25%, Vietnam rises 15%, net +200 units.”

- Win: Save $1M in overproduction, add $2M in sales—$3M swing.

Edge: Big ERP lags a month. Custom’s instant—try our free sync check.

4. Train Your Crew on ERP-Robotics—Fast and Mean

Robots don’t run themselves—your team’s the bottleneck. ERP cuts the learning curve.

- Action: Embed a training module in ERP—schedules, alerts, KPIs. Example: “Day 1: Robot setup, 2 hours; Day 2: ERP input, 1 hour.” Track progress: 80% uptime goal.

- How: Build it simple—PDF guides, timers in ERP, one-day dev. Roll out in a week: 10 workers, 20 hours total.

- Win: Hit full robotic capacity in 14 days, not 60—$1M in output saved.

Hack: Our ERP setups train crews in half the time—see it live, link below.

5. Scale Output with ERP Precision—Crush the Tariff Game

One robot’s a start—10’s a revolution. ERP scales it without breaking.

- Action: Model multi-robot lines in ERP—capacity, cost, bottlenecks. Example: 5 robots, 5,000 units/day at $12/unit, $100K maintenance. Optimize: cut $20K by staggering shifts.

- How: Run simulations—two-day tweak, $500 in dev time. Link to supplier data (Mexico PCBs at $10 vs. China’s $20.40).

- Win: Boost production 20%—$12M extra on a $60M line—while tariffs choke rivals.

Power Move: We’ve scaled 15+ robotic setups this year—get a free integration plan.

Why Custom ERP Fuels the Robotics Edge

SAP’s $150K and six-month lag? Junk. Custom ERP’s $50-100K, deployed in weeks, built for robotics—real-time output, demand sync, lean scaling. The U.S. robotics market’s $50 billion, growing 20% yearly—tariffs (104% China, 25% Canada) say automate or die. S&P’s down 18.9%—recession’s here. You need a tool that fights, not flops.

- Proof: A client added $8M in robotic output with our ERP last quarter. Another cut $3M in waste. That’s domination.

- Next Step: Don’t stall. Grab our free integration plan—30 minutes, yours today.

Wrap-Up: Ride the Robotics Wave, Beat the Tariff Crush

The 104% China tariff and Canada’s 25% counterpunch are your wake-up call—$489 billion in imports and exports are toast. Robotics is your out: 20% cheaper, 24/7 muscle, U.S.-made. Integrate it with custom ERP—assess, connect, forecast, train, scale—or watch rivals bury you. This is a $50B robotics revolution—jump in, or get left.

Action Time: Fill out our contact form and get your custom integration plan. We’ll blueprint your ERP–robotics sync in 48 hours—for just USD 5,000. Move fast—win big.