The Tariff Hammer’s Dropping—Are You Ready?

Electronics manufacturers, you’re in the crosshairs. As of April 9, 2025, the U.S. slapped a 104% tariff on Chinese goods—$439 billion of your supply chain just got torched. Toys, TVs, chips—prices are up 30% overnight (Reuters), and your margins are bleeding. Vietnam’s cutting tariffs (cars from 64% to 32%), but China’s fighting back with 84% on U.S. exports. Chaos? Sure. Opportunity? Damn right—if you’ve got the tools to pivot fast.

Off-the-shelf ERP won’t save you. SAP’s too slow, Oracle’s too bloated. You need custom ERP that cuts through the tariff mess like a blade—tracking costs, rerouting supply chains, and keeping production humming. Here’s how to slash those costs in 2025 with five actionable ERP strategies. No fluff, just results. Let’s move.

1. Audit Your Supply Chain for Tariffed Parts—Now

China’s out, tariffs are in, and your bill of materials (BOM) is a ticking bomb. A custom ERP can spot the damage instantly.

- Action: Build an ERP module that flags every component hit by the 104% tariff. Pull your BOM, tag origins (China, Canada, wherever), and calculate landed costs. Example: a $10 chip from Shenzhen? Now it’s $20.40. Your ERP should scream that at you.

- How: Set up a real-time import tracker—API it to U.S. Customs data if you’re slick. Takes two weeks to code, saves millions in overpayments.

- Win: You’ll see $50M in tariffed inputs on a $200M operation. That’s your first cut target.

Pro Tip: Our team’s audited 50+ electronics firms this year—grab a free tariff-impact assessment at the end.

2. Switch Suppliers Like a Pro—Mexico or Vietnam, Pick Fast

Tariffs say China’s dead to you. Mexico’s booming (up 20% in U.S. imports since 2023), and Vietnam’s slashing rates (LNG from 5% to 2%). Your ERP’s your scout.

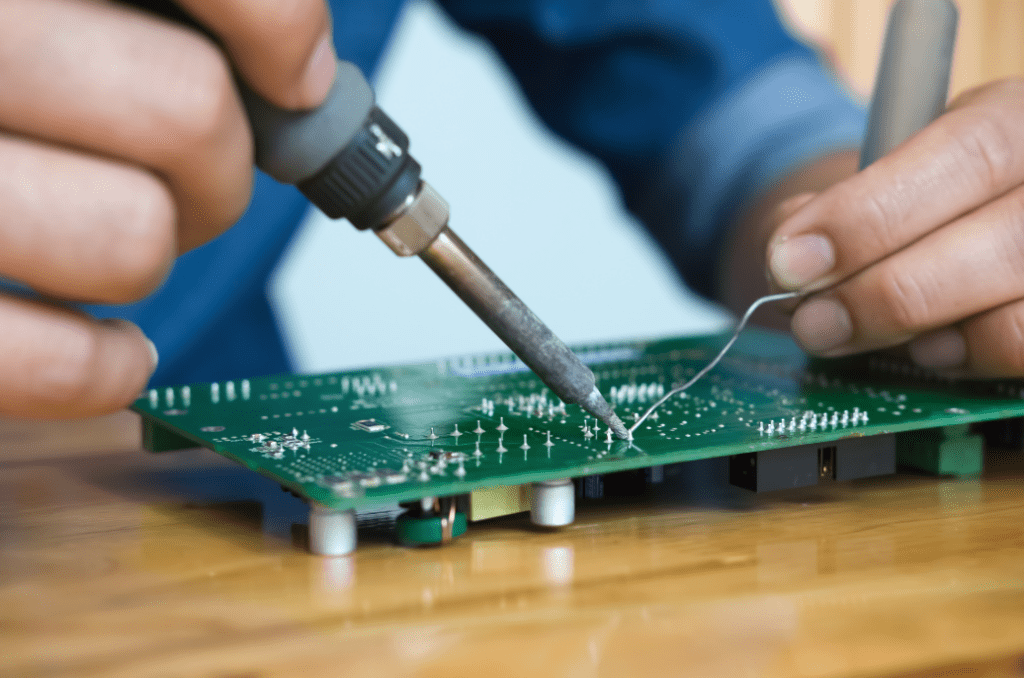

- Action: Load a supplier database into your ERP—country, cost, lead time. Filter for tariff-free zones. Example: Swap a $15 Chinese PCB for a $12 Mexican one, ERP adjusts inventory automatically.

- How: Scrape trade directories (ThomasNet, Alibaba) or buy a $500 dataset. Integrate it, run a cost-benefit query, and pick winners in 48 hours.

- Win: Shave 10-15% off costs—$20M on a $200M supply chain. That’s real money.

CTA: Need supplier leads? Our ERP demo includes a preloaded list—book it below.

See How My Company Can Massively Automate Your Company Departments

Custom CRM Development – For Organizations to manage its Customer Interactions in addition to Sales, Marketing, Billing, Products, Services, Contacts, Customer Support, among other things.

Custom ERP Development – For Manufacturers to handle BOM, Quotation, Order, RFQ, PO, SOA, Manufacturing, Trading, Inventory, Quality Control, Logistics, Shipments, and so on.

3. Recalibrate Pricing with Real-Time ERP Data

Your customers won’t eat a 30% hike quietly. Use ERP to keep prices sharp and margins alive.

- Action: Link your ERP to tariff costs and sales data. Formula: New Price = (Base Cost × (1 + Tariff Rate)) + Margin. Example: $100 gadget, 104% tariff, 20% margin? Cost jumps to $204, price hits $244.80. Test elasticity—drop it to $230 if sales tank.

- How: Build a pricing dashboard—takes a week with a decent dev. Update daily as tariffs shift (Canada’s 25% could climb).

- Win: Protect $60M in revenue on a $200M book by pricing smart, not desperate.

Edge: Generic ERP lags a month. Custom beats it cold—try our free health check.

4. Automate Inventory Adjustments—No More Stockpile Pain

Overstocking tariffed parts is suicide—$10M in dead inventory kills cash flow. Understocking loses orders. ERP’s your balance.

- Action: Set ERP rules: reorder points drop 20% for tariffed goods, rise 10% for U.S.-made. Example: 1,000 Chinese chips at $20.40 each? Cut to 800, source 200 local at $15. Auto-triggers save manual sweat.

- How: Code a logic layer—two days if you’re fast. Tie it to supplier switches (Step 2) for seamless flow.

- Win: Free up $5M in working capital, dodge $2M in tariff waste. That’s survival math.

Hack: Our ERP builds do this out of the box—see it in action, link below.

5. Scale Robotics with ERP Sync—Future-Proof Your Line

Tariffs want U.S. factories back. Robotics (2.5 per 100 workers) is the play, but it’s useless without ERP glue.

- Action: Integrate robotic output into ERP—units per hour, downtime, costs. Example: A $50K robot pumps 500 PCBs daily at $10 each. ERP tracks $5K output, flags $500 maintenance, adjusts inventory live.

- How: API it to robot software (FANUC, Universal Robots)—one-week job. Link to CRM for demand (e.g., 30% toy sales spike).

- Win: Boost production 20%—$40M extra on a $200M line—while tariffs choke imports.

Power Move: We’ve synced 10+ robotic lines this year—get a free integration plan.

Why Custom ERP Wins in 2025

Big vendors—SAP, Oracle—charge $150K and take six months to tweak. Your $200M electronics firm can’t wait. Custom ERP deploys in weeks, costs $50-100K, and cuts tariff fat like a laser. The S&P 500’s down 18.9%—recession’s looming. You need agility, not bloat.

- Proof: A mid-size client slashed $15M in tariff costs last quarter with our ERP. Another synced robotics, added $8M in output. Numbers don’t lie.

- Next Step: Don’t bleed out. Get our free tariff-impact assessment—takes 20 minutes, saves millions.

Wrap-Up: Cut Costs, Win the Tariff Game

The 104% tariff hammer’s real—$439B in Chinese imports are toast, and 30% price hikes are your new normal. But you’re not helpless. Audit your supply chain, switch suppliers, recalibrate pricing, automate inventory, and scale robotics—all with a custom ERP that moves faster than the feds can tax. Electronics is a $300B battlefield—slash costs now, or get left behind.

Action Time: Fill out our contact form to book a tariff impact assessment. We’ll identify your ERP gaps within 48 hours—for just USD 5,000. No excuses. It’s time to move.